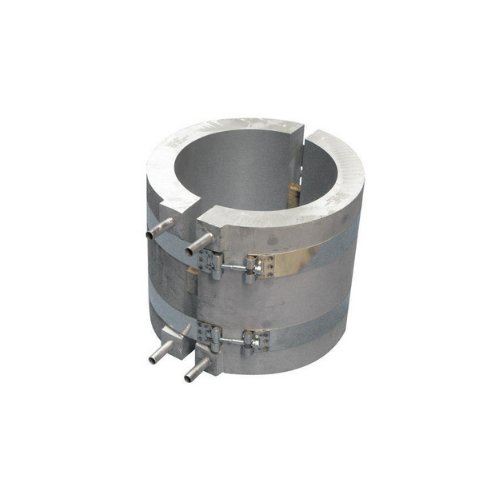

CAST-IN HEATERS

Enquire now Download Catalogue- Brand: Alfa Heaters

- Product Code: standard

- Availability: In Stock

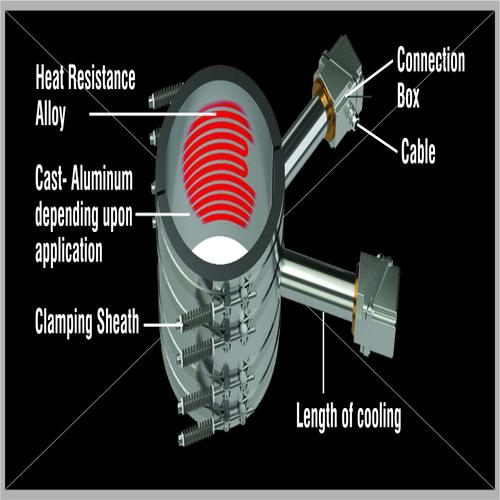

Cast-in heaters are designed for heating solids or indirect heating. Cast-in heating elements are ideal for applications requiring homogeneous indirect heat. Cast-in heaters are often used in plastics industry, packaging industry, food industry and many others. The cast-in heating plates and heating bands consist of one or several electrical resistance embedded in a block of aluminum, brass, bronze or cupronickel alloy providing excellent thermal conductivity.

APPLICATIONS

- Heating plates for presses

- Extruded dies and sheaths

- Heating plates for homogeneous heating (rubber, aerated concrete curing) sealing on packaging lines mill.

Advantages

- High protection against corrosion

- As this is indirect heating, the heating resistance is protected. The solid or fluid to be heated is not in contact with the resistance.

- Gravity moulding ensures an excellent material homogeneity and thus a perfect heat transfer.

- The end-to-end control of the design and production chain allows us to deliver a product which suits your process perfectly

- Can be equipped with cooling circuits to optimize the industrial process thus enlisting them in water cooled heaters and air cooled heaters segments

- Resistance in severe industrial surroundings (impacts, vibration)

FEATURES:

- Indirect heating

- Block of aluminum, brass, bronze or copronickel alloys

- Process temperature up to +400°C (aluminum), +650°C (copronickel). Maximum +750°C.

- Maximum weight: Aluminum 400kg / Copronickel 300kg

- Can be equipped with cooling circuits to optimize the industrial process

Operating Conditions

- Extreme environments: – 60°C to + 80 °C

- Onshore / Offshore environment

- Hazardous areas (ATEX/IECEx) and NEC 505

- Normal (non-ATEX)